During the process of laser cutting, high-power-density laser beam heats the workpiece material to its melting point and vaporizes the material to form a cavity known as a keyhole, thus creating a narrow kerf as the beam travels along the workpiece.

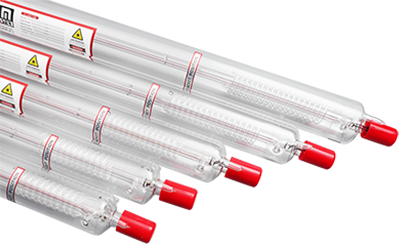

Recommended Products Features of Our CO2 Laser Tube- Providing stable power;

- Applicable to a wide range non-metal materials;

- Can achieve smooth cutting edges without any defects, free from deformation;

- High perpendicularity of cut, particularly suited to cut materials requiring high cutting precision;

- Various shapes, patterns or drawings can be designed and created through computer software, eliminating the need for any cutting molds;

Examples of Laser Cut Products

-

- Acrylic cutting

- Thickness 30mm (H6/M6 130W CO2 Laser Tube)

- Thickness 35mm (H8/M8 150W CO2 Laser Tube)

-

- MDF cutting

- Thickness 10mm/15mm (130W/150W CO2 Laser Tube)

-

- Fabric cutting

- Cutting speed: 75W 100mm/s, 90W 200mm/s, 100W 300mm/s, 130W 400mm/s, 150W 500mm/s

-

- Leather cutting

- Cutting speed: 75W 20mm/s, 90W 25mm/s, 100W 45mm/s, 130W 35mm/s, 150W 40mm/s

Laser Engraving

Laser engraving is a process which uses laser as the machining medium on the basis of numerical control technology. The laser emitted from laser source creates marks on the workpiece by melting and vaporizing the surface ...

Read More

Laser Marking

Laser marking is a process that uses high-energy density laser to locally irradiate the workpiece, enabling the surface material to be vaporized and causing a chemical reaction to change color, thus leaving a permanent mark.

Read More

Main Products

Why Choose Us

More than 20 years in the laser market since 2002

Professional R&D team of experts who have worked in the field of laser cutting machine and laser tube

HM Laser's high-efficiency production and strict quality control processes

Advanced Glass-to-Metal Hard Seal technology, the premium quality metal head for sealed CO2 laser tube

Reflective mirror (US II-VI) + discharge tube (German Schott) + catalyst coating (HM Laser), with good configurations of resonant cavity

Self-developed high-precision machining center ensures the high precision of optical components

Ultra-clean workshop, constant temperature and humidity are maintained to guarantee consistent quality of laser tubes all year round