In 2002, HM Laser started a growth path in the BDA (Beijing Economic-Technological Development Area). At the very beginning of our business, we were a laser engraving and cutting machine agent for USA EPILOG Corporation and have introduced the first CO2 laser engraving and cutting machine into China market therefore pioneering the domestic industry of non-metal laser processing, spanning across a multitude of industry sectors such as signage, craft gifts, clothing, shoe making and leather processing.

In 2005, we gradually expanded our business by supplying lasers as an agent of IPG Photonics and have helped many metal works factories improve their production efficiency. For nearly 30 years we have spent in the field of laser development and application, and we pride ourselves in providing thousands of customers worldwide with our premium quality products and excellent services.

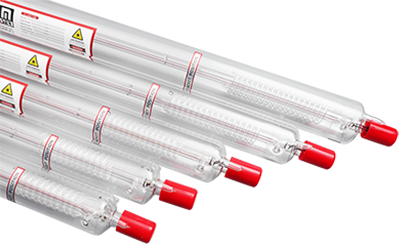

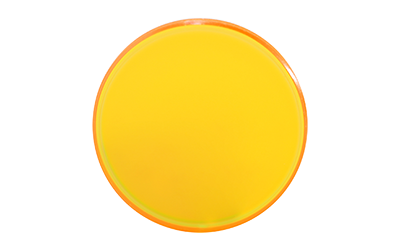

Today, HM Laser has developed into a trusted brand of CO2 laser tubes and is the agent for SCAPS control cards and SAM Light software in Germany. Our professional R&D team has been working in the CO2 laser tube and laser engraving and cutting equipment industry for more than 20 years. As an experienced brand of laser optics, HM Laser knows that cost effectiveness and optical accuracy are the two most important criteria. To this end, we have established a complete quality management system and a self-optimizing operation system to improve optical accuracy. Our laser tube stability and consistency reach the highest level in the industry.

HM laser continues to strive to earn the ongoing trust of our customers by sharing our advanced technology, improving our laser products, and providing the best services to meet the specific needs of our customers all over the world.

Why Choose Us

- More than 20 years in the laser market since 2002

- Professional R&D team of experts who have worked in the field of laser cutting machine and laser tube

- HM Laser's high-efficiency production and strict quality control processes

- Advanced Glass-to-Metal Hard Seal technology, the premium quality metal head for sealed CO2 laser tube

- Reflective mirror (US II-VI) + discharge tube (German Schott) + catalyst coating (HM Laser), with good configurations of resonant cavity

- Self-developed high-precision machining center ensures the high precision of optical components

- Ultra-clean workshop, constant temperature and humidity are maintained to guarantee consistent quality of laser tubes all year round