-

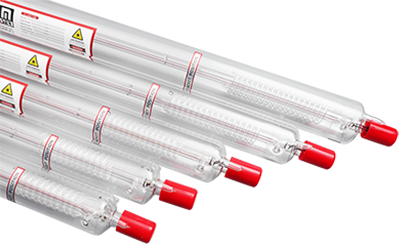

How long can a laser tube serve?

Usually, the service life of different models of laser tubes ranges between 10,000 and 15,000 hours. It depends on a variety of factors, including operating environment, working hours, power settings, as well as operator experience and skills. So, the life cycle of a laser tube can last for a period of one year, or several years.

-

Who is responsible for the loss if laser tube gets accidentally damaged during transport?

First of all, we have to rule out the possibility of intentional man-made destruction. HM Laser conducts proven approach to pack products in a professional manner, which makes products secured even if they are loaded and unloaded in a careless way. Besides, the laser tube packaging boxes we use have the highest level in quality.

Secondly, we recommend DHL as the carrier to transport your products. DHL can not only deliver excellent service and higher discount, but also has high compensation insurance rates provided by cooperative insurers. -

What about the shipping cost of laser tube?

The standard freight pricing for international shipment is based on weighing, size measuring, and volumetric weight calculating by multiplying the dimensions (length, width and height) and then dividing that by 5000. The greater of the actual weight and volumetric weight will be utilized to calculate shipping cost.

-

How can I get warranty service if the laser tube has an issue?

Within the warranty period, if there is a power problem of laser tube, please send us video that shows operating current, working status and factory label. The video can run starting from power meter, high-voltage end, low-voltage end, through to factory label.

When it comes to laser spot problem, please test the light spot quality at the light outlet of the laser tube. The light spot tested at second reflector, third reflector and focus lens will not be recognized. -

What is the reason why the laser tube does not emit light?

Laser beam is generated by applying a high-voltage DC power supply to excite the CO2 gas in a glass tube. That means, the intensity of laser light depends on energy level. No matter it is a laser engraving machine, laser cutting machine or laser marking machine, the possible reasons why the laser tube does not emit light are as follows:

1. No signal from control card of laser equipment for laser tube power supply, so there is no power for laser generation;

2. Faulty power supply, can not send power to laser tube;

3. Laser tube is damaged; -

How to protect laser tube from freezing?

When laser machines are used in an environment where power failures frequently occur or there is no condition to empty the cooling water every day, adding antifreeze is a must to prevent your machine from freezing in the cold weather. Antifreeze does not cause rust or corrosion of metal parts, rubber hoses and other accessories of laser machine. When selecting the antifreeze, it should be noted that the freezing point of antifreeze agent has to be 5℃ below the lowest temperature of operating environment.

1. Using ethanol as an antifreeze for short-term treatment

When power failure occurs or it is difficult to empty cooling water, ethanol may be used as a temporary treatment for short-term antifreeze by adding it in deionized water or pure water. The adding volume can not exceed half full of the tank. Considering that ethanol has highly corrosive effects, the ethanol mixture must be emptied within a week and it is necessary to clean the cooling pipeline with pure or deionized water.2. Using special antifreeze of professional brands

Professional brand antifreeze is recommended, generally two models of antifreeze especially for laser engraving machine:

Antifrogen N (ethylene glycol based coolant): industrial product, toxic to human beings;

Antifrogen L (propylene glycol based coolant): food grade, non-toxic to human beings;

These two types of coolant can be easily found in the market.

Note: there is no antifreeze can entirely replace deionized water for continuous use through the year. When the winter is over, deionized water or pure water has to be used to clean the pipeline and used as the cooling water. -

How to maintain and clean the window mirror of laser tube?

Firstly, a high-efficiency fume collector is required to reduce the laser tube exposure to airborne contaminants generated during laser cutting.

Then, laser tube window mirror has to be cleaned by blowing the mirror surface with air blower before powering on and after powering off, or gently wiped using ethanol-soaked nonwoven swab once a week. -

What are the optimal conditions for operating laser tube?

The voltage stability of power supply should be maintained without high-power or strong radiation interference. A regulated power supply can be configured to mitigate large voltage fluctuations. Laser engraving and cutting machines must have good grounded power connection. All laser processing equipment should be placed on a flat and stable floor, and can not be operated in working environments where have high vibration and humidity.

-

What are common problems of laser tube used in laser marking machine?

The laser light is weak or cannot be emitted, it means that the laser tube is damaged if control card and power supply can work properly.

The spot size is relatively large and rough marking is created, laser tube has to be changed. -

How to choose CO2 laser tube?

Many factors can affect the quality of products processed using CO2 laser tube, such as components, manufacturing processes and design parameters. The quality of a laser tube can be reflected in aspects of laser power, beam spot quality, stability and lifespan. When selecting a right CO2 laser tube, the power of laser tube needs to be considered according to the material of workpiece. The spot quality is determined by multiple steps of production process, laser spot size will directly influences the performance of laser equipment. The high stability of laser tube can help avoid problems such as gas leakage and burst. Because the laser tube is a kind of laser consumables, the service life must be a major consideration when selecting a laser tube.

-

How to maintain laser tube?

As we mentioned above, a good operation environment is required firstly. Laser processing equipment should be placed on a flat and stable floor, and can not be operated in working environments where have high vibration and humidity. The voltage stability of power supply should be maintained without high-power or strong radiation interference. A regulated power supply can be configured to mitigate large voltage fluctuations.

In addition to these, the current of laser should not be too large, and the laser beam should be kept at low intensity as much as possible under the conditions of satisfying the processing speed and requirements. And make sure there is sufficient cooling circulating water at a temperature range of 5-25℃, deionized water is an ideal option. The cooling water should be changed regularly.

Lastly, focus lens should be wiped frequently to keep it clean.