In 2002, HM Laser started a growth path in the BDA (Beijing Economic-Technological Development Area). At the very beginning of our business, we were a laser engraving and cutting machine agent for USA EPILOG Corporation and have introduced the first CO2 laser engraving and cutting machine into China market therefore pioneering the domestic industry of non-metal laser processing, spanning across a multitude of industry sectors such as signage, craft gifts, clothing, shoe making and leather processing.

Read More

During the process of laser cutting, high-power-density laser beam heats the workpiece material to its melting point and vaporizes the material to form a cavity known as a keyhole, thus creating a narrow kerf as the beam travels along the workpiece.

Learn More About Laser Cutting

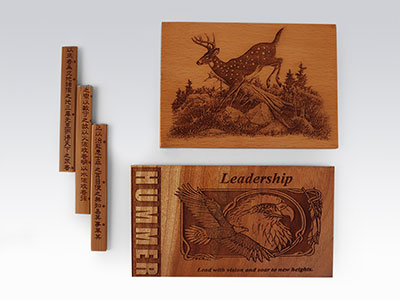

Laser engraving is a process which uses laser as the machining medium on the basis of numerical control technology. The laser emitted from laser source creates marks on the workpiece by melting and vaporizing the surface, therefore achieving the aim of laser processing.

Learn More About Laser Engraving

Laser marking is a process that uses high-energy density laser to locally irradiate the workpiece, enabling the surface material to be vaporized and causing a chemical reaction to change color, thus leaving a permanent mark. Laser marking technology is one of the most widely used laser processing methods across a multitude of industry sectors.

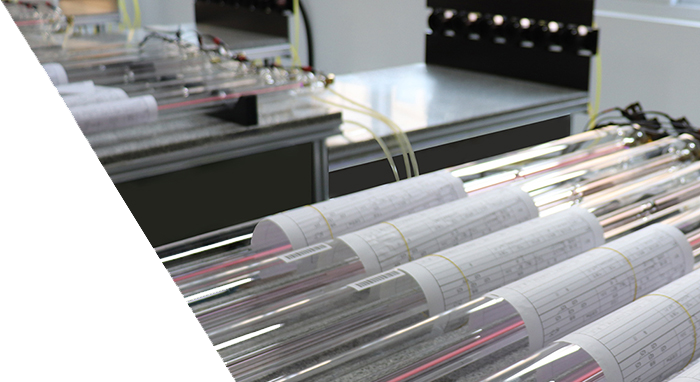

Learn More About Laser MarkingOur R&D team of seasoned professionals has worked in the laser tube industry for 20 years, and constantly strives to push the limits of our know-how to develop high-quality metal head laser tubes to adapt to the market needs.

Read More

More than 20 years in the laser market since 2002

Professional R&D team of experts who have worked in the field of laser cutting machine and laser tube

HM Laser's high-efficiency production and strict quality control processes

Advanced Glass-to-Metal Hard Seal technology, the premium quality metal head for sealed CO2 laser tube

Reflective mirror (US II-VI) + discharge tube (German Schott) + catalyst coating (HM Laser), with good configurations of resonant cavity

Self-developed high-precision machining center ensures the high precision of optical components

Ultra-clean workshop, constant temperature and humidity are maintained to guarantee consistent quality of laser tubes all year round